9/25/2025

Article

This year, Rototilt Group has adopted a new company-wide target. The goal takes a broader perspective on sustainability and includes product efficiency, the reduction of Scope 3 emissions in the supply chain, as well as waste and recycling. CEO and co-owner Anders Jonsson explains:

“Last year was eventful for us at Rototilt, both globally and locally. We took a big step forward by introducing a fifth overall target, which we call Climate Responsibility. This goal is based on science-based methods and measurable indicators to reduce climate impact and strengthen our long-term sustainability efforts.”

The new climate target has also paved the way for expanded sustainability reporting, something Ida Skaring, Sustainability Strategist, has played a key role in driving.

“At Rototilt, it’s not just about keeping up, but about being one step ahead. I believe there’s a clear mindset in the company that we work with sustainability because we want to, not just because we have to. And this applies to all perspectives of sustainability—ecological, economic, and social. Rototilt is a major employer in Vindeln, and there is a strong will to take responsibility as a community partner and give back through events and other initiatives,” Skaring explains.

Energy-efficient factory expansion

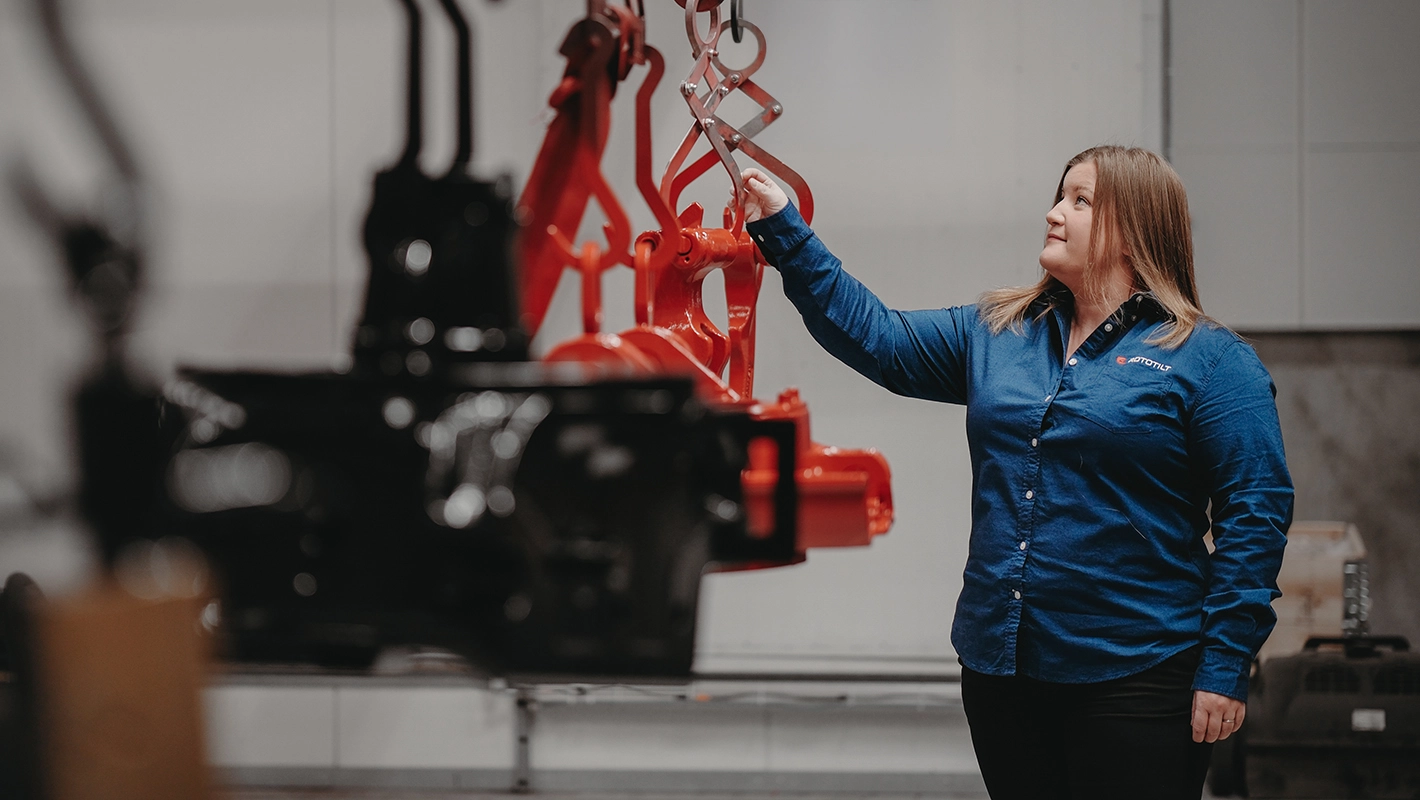

The climate perspective is present at every level, not least in the development of the factory in Vindeln. In 2024, a new factory expansion of 1,080 square meters over two floors was completed. It now houses a new robotic welding facility for the production of machine couplers. Both the expansion and the facility place energy efficiency front and center and have allowed Rototilt to bring part of the welding production back to Sweden.

“By using heat recovery, we can effectively capture surplus heat generated during production. This helps us reduce the need for primary energy and lower our emissions, contributing to both environmental and financial benefits. It’s a central part of our journey toward a more circular operation.”

The facility went into operation in spring 2024 and has already delivered several positive results. Skaring continues:

“Our goal is not only to provide innovative products but also to operate a production facility that meets the highest sustainability standards. The new robotic welding facility is a strong example of how the two go hand in hand.”

A Group-wide initiative

Sustainability work does not only apply to the factory in Vindeln—it applies across the entire Group, including operations in international markets. Part of Ida Skaring’s role is to support subsidiaries in their sustainability work, which has, among other things, resulted in Rototilt Inc. achieving ISO certification for its operations in Canada:

“Sustainability efforts are driven centrally from our headquarters here in Vindeln, but our targets are the same in every country where we operate, and we report as a Group. In addition, we are working to make sure our goals increasingly cover the entire value chain, from supplier to end customer and onward to recycling. We have also made great progress with our new sustainability strategy, which will further highlight how we should address these issues and improve our ability to take a full life-cycle perspective.”

The new climate target, combined with sustainability reporting and strategy, lays the foundation for continued improvements both in the factory and globally—and we are already seeing positive results.